Propylene glycol is used in a variety of products, including cosmetics, food additives, and pharmaceuticals. It also serves as a solvent for other chemicals.

What is Propylene Glycol?

Propylene Glycol is a synthetic

liquid used in a wide range of applications such as pharmaceuticals, cosmetics,

food, and manufacturing industries. It is an alcohol that absorbs water and

mixes with many solvents, made primarily made by treating propylene oxide from

refining petroleum with water.

It is used to absorb

extra water and retain moisture in medicines, cosmetics, or foods.

As a solvent, it is used in the food,

paint, and plastic industries. Also, propylene glycol is used in theatrical productions and

firefighting training to simulate smoke or fog.

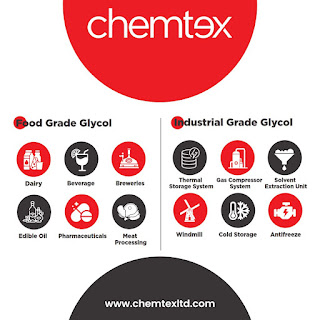

Major Application Areas

Pharmaceutical

Pharmaceutical-grade

propylene glycol USP/EP is used as a non-active enabling agent, also known as

an excipient. As an agent, it carries flavors in food and beverages, helps

retain taste and moisture in pet and livestock feed, and acts as a carrier of

active ingredients found in cough syrup and gel capsules.

Industrial

Industrial-grade

propylene glycol is used as a heat-transfer medium that protects against

pressure bursts and corrosion, controls viscosity, and dissolves active agents.

Industrial propylene

glycol is also used in paints and coatings for wear and weather protection, as

an aircraft in liquid detergents, and antifreeze, and as a solvent in printing

ink.

As a basic building

block, it is used in its raw form to make formable plastics like unsaturated

polyester resins. The resins are used in windmill blades, furniture, marine

construction, gel coats, synthetic marble coatings, and sheet molding compound

and for heavy-impact surfaces such as floors.

In Cosmetics.

As a Deodorant Alternative: Propylene glycol can serve as a

deodorant alternative because it works by absorbing moisture. This means that

it will not leave any residue behind after use.

It can also be used as a solvent in nail polish removers.

Propylene glycol keeps

personal care products consistent, soft, and moist. This includes deodorant

sticks, sunscreen, shampoos, body lotions, face creams, and lipstick.

Additionally, it works as an excipient to stabilize foam in personal care and

health care products.

As a Food Additive.

Propylene glycol is commonly used as a food additive because it

helps keep foods fresh longer. It is also used as a solvent in cleaning

products.

In Medicine.

Propylene glycol can be found in medicine as a solvent. It is

often used to dissolve medications such as insulin and antibiotics.

As a Fuel Additive.

Propylene glycol is also commonly used as a fuel additive. This

means that propylene glycol is added to gasoline to make it burn more

efficiently.

Chemtex Propylene

Glycol Antifreeze

Chemtex manufactures Corrosion

Inhibited Propylene Glycol-based Antifreeze with its unique combination of

properties supporting many end-use applications.

Primary functions as

drawing away heat, and allowing the engine to operate efficiently, with lesser

malfunctions and damages to its parts. The inhibitor package inhibits glycol degradation,

not allowing sludge deposition, while increasing the glycol operational life

and metallurgy, whilst not affecting freeze protection properties. Also

designed to protect brass, copper, steel, cast iron, aluminum alloys, and other

components such as rubber hoses, rubber seals, plastic components, etc.

Chemtex Propylene Glycol based HTF

is NSF Certified for use as a Heat Transfer Fluid with Incidental Food Contact.

It is also listed with FSSAI under Food Product Category 99 for Substances

added to Food.

Check out our range of propylene and ethylene glycol antifreezes at https://www.chemtexltd.com/products-and-solutions/heat-transfer-fluid/glycol-antifreeze/